When we refer to Enterprise Asset Management (EAM), we can refer to two elements:

- A set of processes and systems dedicated to managing physical assets.

- A software tool that helps manage physical assets.

The first definition responds to EAM as an area responsible for managing everything related to assets within an organization.

On the other hand, the second definition responds to the embodiment of this definition: software capable of centralizing all aspects of asset management within an organization.

3 keys to understanding Enterprise Asset Management

1. What is EAM?

Also known as Enterprise Asset Management, EAM comprises a set of software solutions, processes, and systems brought together in an application used to manage an organization’s physical assets.

All of this is condensed into software that allows the lifecycle of enterprise assets to be managed from one place, from planning, maintenance, repair, operations, associated labor management, and even the financial aspect related to asset management.

2. What is the purpose of EAM?

Organizations with robust cloud infrastructures and networks of assets to monitor can leverage EAM software to:

- Centralize asset management.

- Optimize asset usage and maintenance.

- Improve operational efficiency.

- Reduce costs.

- Extend the useful life of assets.

In addition, another benefit of using EAM software in an organization such as the one described above is improved visibility into everything related to the company’s assets.

For example, with EAM software, asset managers can access the information they need about the entire lifecycle of the organization’s assets.

In addition, they will be able to monitor in real-time the status of each asset to optimize their use. Moreover, this helps to comply with regulations such as ISO 55000.

Enterprise Asset Management Use Cases

3. How do all these EAM concepts apply in the real business world?

We will take as examples 2 different industrial sectors:

Manufacturing

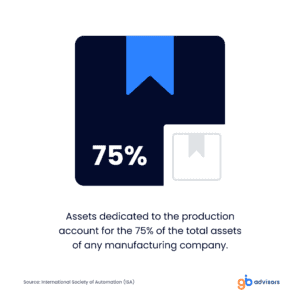

One of the biggest challenges for companies in this sector is to manage the large number of assets they handle.

What kind of assets does a manufacturing company manage?

Depending on the organization’s niche, a manufacturing company will need to manage equipment dedicated to production (e.g., CNC machines, lathes, milling machines, stamping machines, or plastic injection molding machines).

In addition to this dedicated production machinery, there are other assets such as material handling machinery (cranes or forklifts), as well as transport vehicles or IT hardware.

This is only a fraction of all the assets that a manufacturing company has.

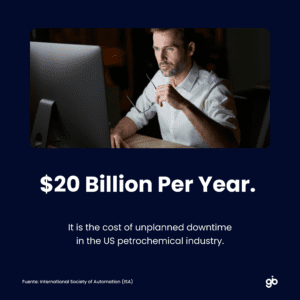

This is the main reason to keep an eye on all these assets, as poor management of aspects such as maintenance can wreak havoc on operations.

[Image: What is the cost of asset downtime? In the U.S. petrochemical industry alone, the cost of unplanned downtime amounts to $20 billion per year. Source: International Society of Automation (ISA)]

Healthcare

In the case of healthcare institutions, EAM software can help make the difference between quality service and poor service.

Why? Because having this type of solution simultaneously covers three vital areas of any healthcare service:

- Availability

- Resource management

In terms of availability, EAM software can help ensure the complete availability of all available assets. How does it accomplish it? With and resources by facilitating real-time monitoring.

With this, this data can be used to stipulate the regularity of maintenance of these assets to prevent them from failing and the service from being affected.

On the other hand, having EAM software allows, for example, monitoring the utilization of any of the equipment in operation. In this way, they can analyze usage patterns, and reuse or relocate equipment to areas that need it.

By tracking usage data, facilities can identify underutilized equipment and make informed decisions about replacement or redeployment.

This approach can help reduce costs and improve the quality of health services for customers.

Why consider EAM for your organization?

Having EAM software brings organizations closer to the operational efficiency they have always sought.

From this operational standpoint, Enterprise Asset Management helps to:

- Enables the management of large amounts of assets without requiring more human talent.

- Optimize how all phases of the asset lifecycle are managed.

- Helps cut any detrimental costs caused by asset misuse.

Things like real-time monitoring of each asset provided by the analysis of data provided by the system helps with asset maintenance.

As a result of using EAM software, any company gets into a context where they can safeguard business continuity, use resources efficiently, and strengthen their operations in times of uncertainty.

If you want to know more in detail how to improve the efficiency of processes in your organization, contact us and learn how you can take this and bring it to your company through software.